What Are the Maintenance Tips for Wire Ropes Used for Hoisting Machinery?

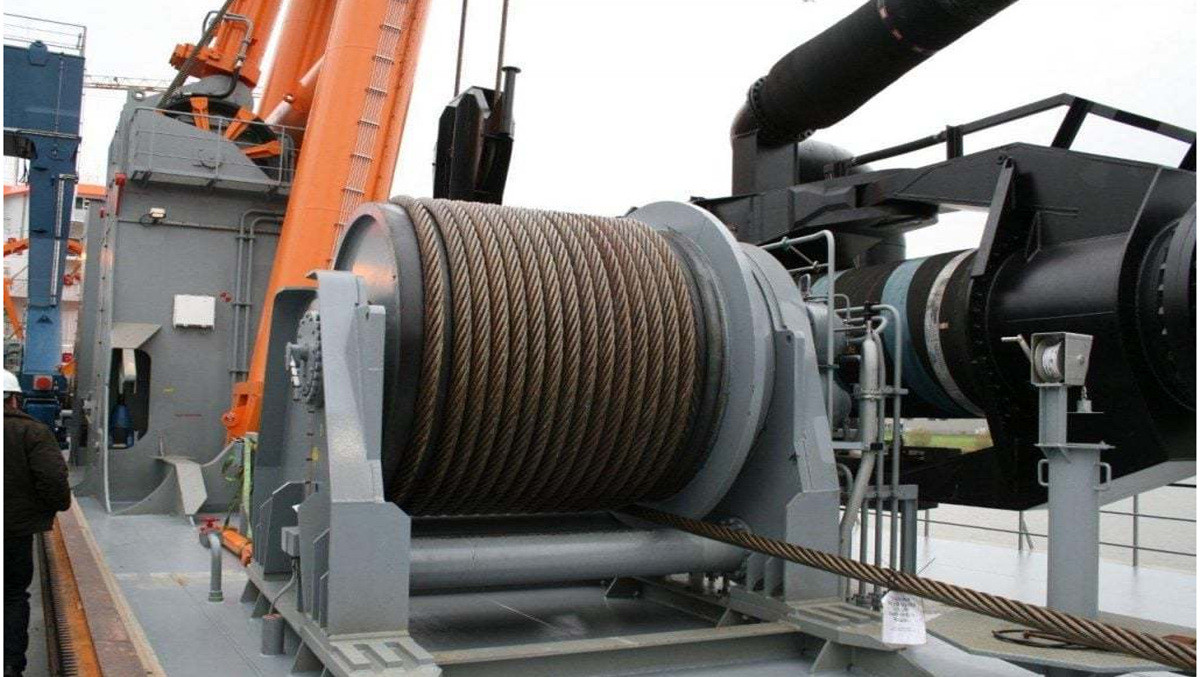

Because of the compact layout of the crane components, the wire rope needs to go around more pulleys, and the diameter of the drum and the pulley is small, which limits the winding diameter ratio (D/d).

Therefore, the bending fatigue resistance performance should be emphasized when selecting the steel wire rope, and the steel wire rope with a small diameter, uniform thickness, and good flexibility should be selected. Usually, 6-strand, 8-strand wire contact strand steel wire rope is listed as the first choice.

When the wire rope is used in a large number of lifting operations, its structure will be very easy to wear. If we can do the following daily maintenance precautions, we can ensure the good mechanical properties of the wire rope.

1. Pay attention to daily observation and regular inspection of the abnormalities and hidden dangers of various parts of the steel wire, which in itself is the best maintenance of the steel wire rope. The most effective measure for the maintenance of the wire rope is to clean and apply lubricating grease to the working wire rope properly.

2. When there are rust stains on the working wire rope or a large number of dirt agglomerates on the rope, in order to eliminate the rust and eliminate the corrosion damage to the wire rope by the dirt, the wire rope should be removed for cleaning and decontamination maintenance.

3. The cleaned steel wire rope should be coated with lubricating oil or grease in time. In order to improve the penetration effect of lubricating grease, the cleaned steel wire rope is often put into the lubricating grease heated to 80~100℃ to soak until it is saturated so that the grease can fully penetrate the rope core.

When the steel wire rope is working again, grease will continuously leak from the core of the rope into the gaps between the steel wires and the rope strands, which can greatly improve the friction between the steel wires and the rope strands and reduce the degree of wear damage.

At the same time, the grease overflowing from the core of the wire rope will reduce and improve the wear between the wire rope and the pulley, and between the wire rope and the drum.

If there is not much dirt on the wire rope, you can also apply lubricating oil or grease directly on the important parts of the wire rope, such as the rope section that often contacts the pulley and drum, and the rope section of the rope end, to reduce the wear of the wire rope.

4. The rope groove of the drum or pulley should also be cleaned frequently. If the rope groove of the drum or pulley is damaged and the wire rope is damaged, the drum and pulley should be repaired or replaced in time.

5. When the lifting wire rope has more than four branches, it is common for the wire rope to slip and twist in the air when there is no load. At this time, the wire rope should be removed in time, and the wire rope should be straightened in a free state to relax and remove the kinks and then reinstall it.

6. For hoisting lashing ropes, in addition to proper cleaning and oil immersion maintenance, the main thing is to always pay attention to padding to protect the steel wire rope from being cut by the edges and corners of heavy objects, and pay special attention to the lashing rope to avoid dust, sand and coal as much as possible. Powder slag and acid-base compounds contact, once contacted, it should be cleaned up in time.

Strictly following these maintenance precautions can also guarantee the safety factor of the wire rope to the greatest extent. If you want to know more about wire rope after reading the above, please contact TERADA for a comprehensive solution.

TERADA has become one of the leading hardware manufacturers with years of experience and excellent manufacturing technology. We put the quality of our products first, equipped with a professional production system and strict quality inspection system. Our products are widely used in various industries and have received unanimous praise from many customers. In order to provide customers with a better sense of experience, we can also develop effective solutions for users and provide thoughtful one-stop services. If you want to buy our wire rope, please contact us immediately!

TERADA HARDWARE

TERADA HARDWARE