Depending on the processing method of the product, the mold can be divided into five categories: punching and cutting die, bending die, drawing die, forming die and compression die.

a. Punching and cutting die: It is done by shearing. Commonly used forms include shearing die, blanking die, punching die, trimming die, whole edge die, hole punching die and punching die.

b. Bending mold: It is a shape that bends the flat blank into an angle. Depending on the shape, precision and production volume of the part, there are many different types of molds, such as ordinary bending dies, cam bending dies, and crimping. Dies, arc bending dies, bending punch dies and twisting dies.

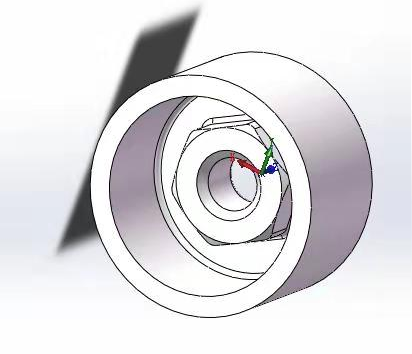

c. Draw mold: The draw mold is a flat blank container made of flat blanks.

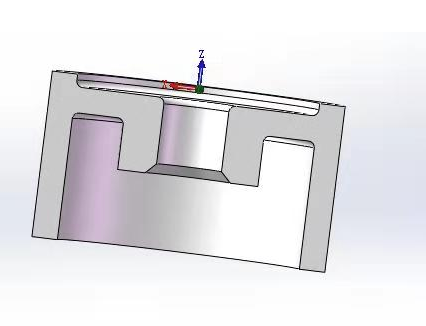

d. Forming Mold: refers to changing the shape of the blank by various local deformation methods, in the form of a convex forming die, a curl forming die, a neck forming die, a hole flange forming die, and a round edge forming die.

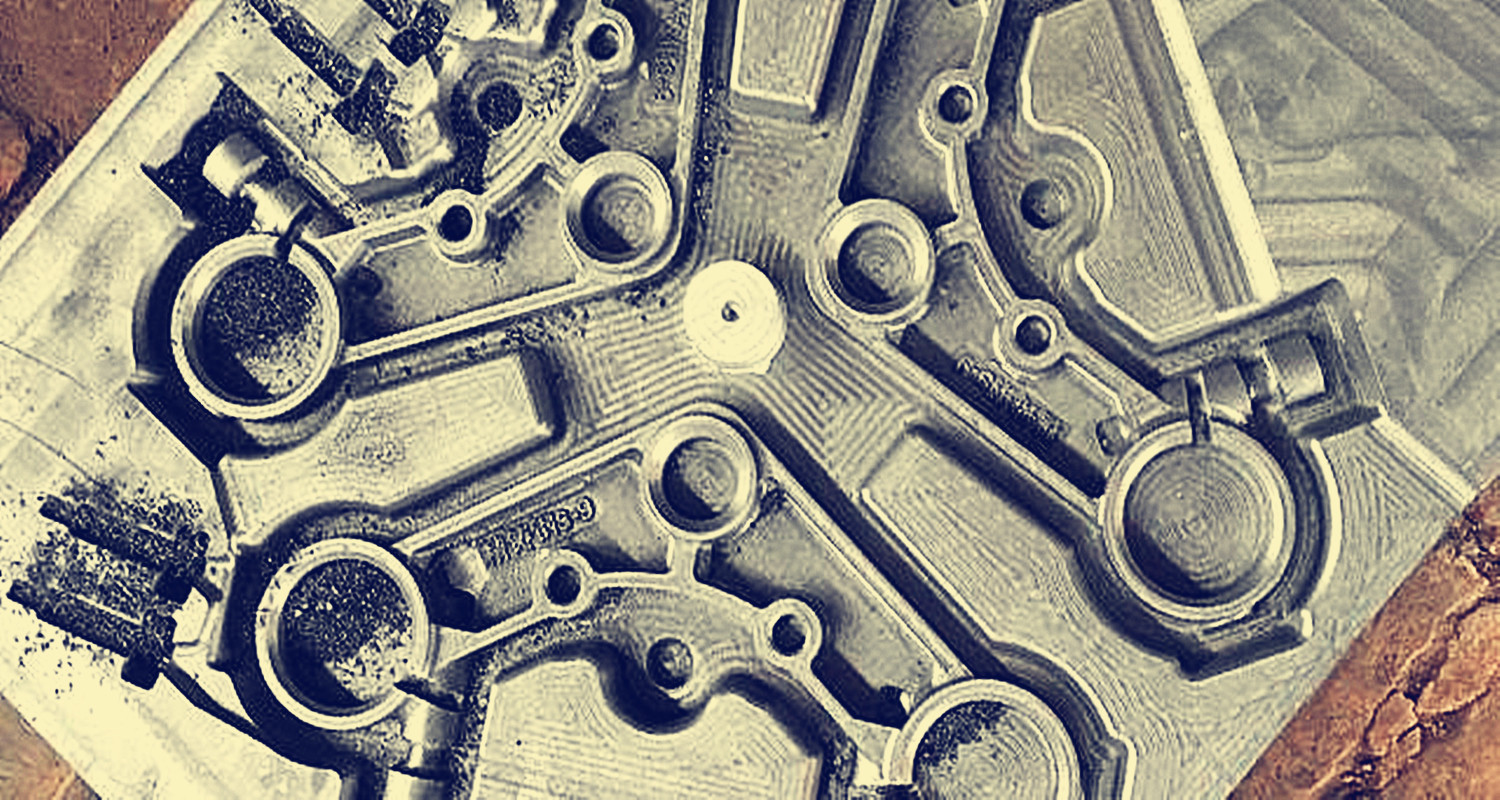

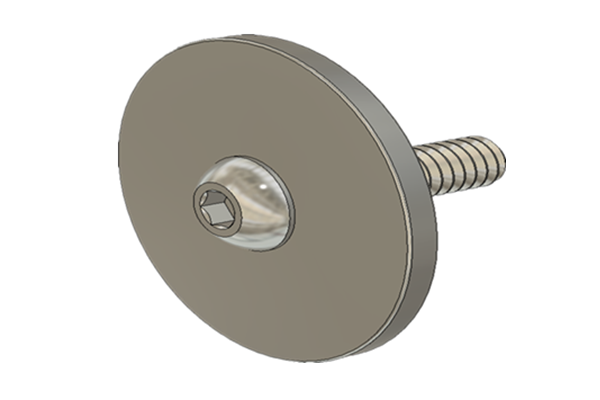

e. Compression mold: It uses strong pressure to deform the metal blanks into the desired shape. The types include extrusion dies, embossing dies, embossing dies and end dies.

TERADA HARDWARE

TERADA HARDWARE